manufacturing.

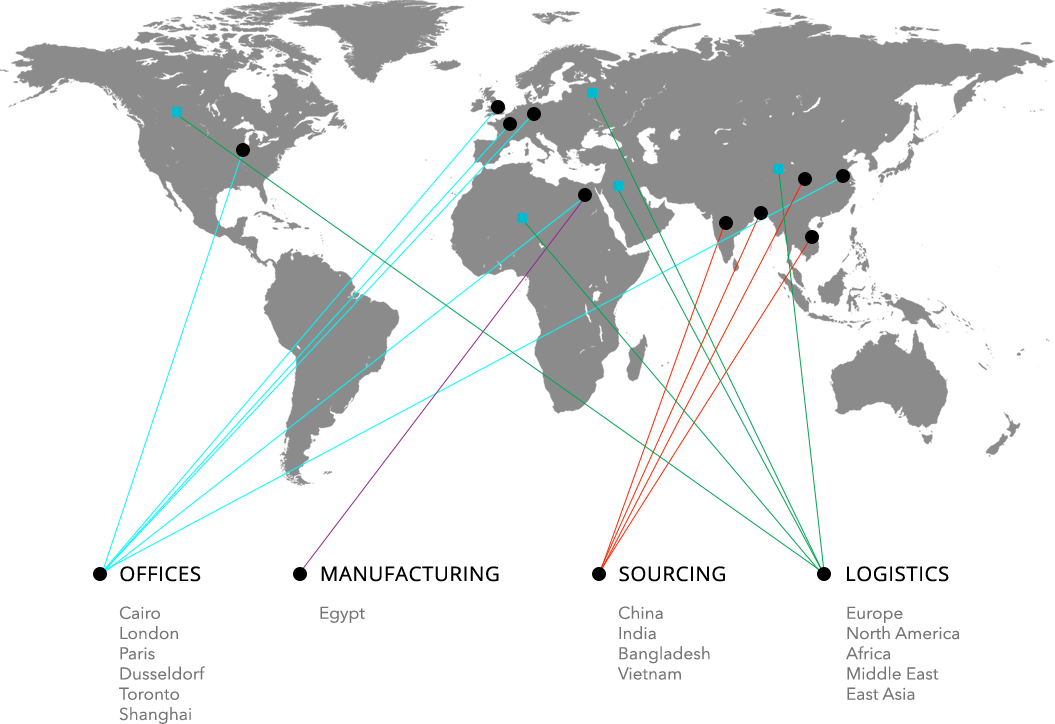

Member of AMETHIS Group of Companies,KTG is a London-based garment and textile supply chain solutions provider serving clients worldwide. KTG offers fabrics, linens, and garment manufacturing through state-of-the-art facilities in Egypt, India, Bangladesh, Vietnam, and China. With offices and warehousing facilities in the UK, Germany, France, Canada, the USA, Egypt, Dubai, Riyadh, and Shanghai, KTG provides fully integrated services—from design and sourcing to manufacturing, warehousing, shipping, and distribution.

KTG also owns and operates Promodoro GmbH, a German fashion brand specialized in corporate, promotional, workwear, and casual fashion. Egyptian-based KTC Hospitality manufactures and supplies luxury linens and terry toweling collections to global hotel brands, restaurant chains, and specialty clients around the world.

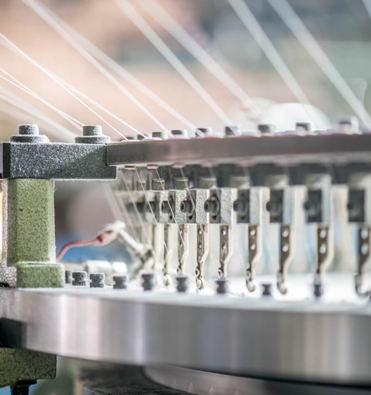

KTG operates two design and development centers, one in Düsseldorf and one in Cairo, serving all KTG brands, factories and sourcing partners. This includes original design work, pattern making, sampling, fabric development and final sampling. We lend our extensive design experience to ensure clients’ designs are production-ready and that the final garment represents their exact vision. We work with buyers, merchandisers, and design teams from design initiation right to production stage through planning, studies, patternmaking, cutting, and production using the latest 3D visualization and physical sampling. We are a vertically integrated knitting and weaving operation using the most modern systems to produce a wide variety of fabrics for our customers across Europe, USA, GCC and MENA. We start with contamination-free recycled yarns and sustainable fabrics to produce our apparel, uniforms and fine linens. The materials range from 100% polyester, to poly blends to 100% cotton and the fabrics include all knitted and woven structures.

What

we produce

Quality at all KTG factories is an integral part of the manufacturing process. In addition to obtaining and adopting the ISO 9001 certification which we employ at every step of the process, we have designed the best quality assurance system that covers every activity with checks and balances along the way. KTC factories employ more than 300 staff that are totally dedicated to the quality of the products we make and sell. Final inspection under 2.5 AQL is our minimum standard. Our certifications represent an instrument through which our customers can be sure they are getting the best products on the market made according to the best industry practices. KTG has set up automated and physical quality control and inspection checks along the entire production process. KTG facilities are proud holders of the following international certifications: ISO 14001, ISO 45001, Intertek, WRAP, OEKO-TEX® STANDARD 100, OEKO-TEX® STeP, Better Work, SCAN, EOS, Global Organic Textile Standard (GOTS), Global Security Verification, Fair Labor Association, Fairtrade Cotton, Egyptian Cotton (Gold Seal), EUROCERT, Supplier Qualification Program, Mill Qualification Program, and the Higg Index.

sourcing.

Fabric Manufacturing

Polyester Yarn Spinning

Jacket Manufacturing

Yarn Spinning

Jacket

KTG’s sourcing mission is to always assure our clients all over the world that our partnership goes beyond manufacturing assets. We are ready to supply and service our clients from whichever country or region based on the best production quality and cost. Sourcing capabilities at KTG is defined as our ability to manufacture the same product quality (as well as other products like winter jackets, and garments) at third party facilities in CHINA, INDIA, BANGLADESH, VIETNAM. This ability involves specialized skills in production management, merchandising, quality assurance, sampling, costing, storing and distribution. Our sourcing partners form an added strategic value that KTG leverages in terms of core competences of certain manufacturing hubs, low cost textile centers, and expertise. KTG’s inspection and quality standards apply uniformly to items coming out of our own factories or contracted to our sourcing partners. WanLoo - Egypt covers labeling and post-production garment requirements either at the point of production or in one of our pick and pack locations before they are shipped to their final destination.

Logistics.

Our warehouse logistics facilities in Cairo, Dusseldorf, Shanghai,Riyadh and Toronto allow the safekeeping of any size order until it is ready for delivery. They ensure the best possible storage, picking-and-packing, and management of your goods. It is an extensive network that offers the most efficient solution for short and long term storage requirements. We work with our clients to their exact needs with full transparency and management of their stock with real-time visibility and transaction records.

We provide full shipping and distribution services to fashion merchandise from Egypt, China and Bangladesh to the United States, Europe and the Middle East. By stocking in our own facilities strategically distributed worldwide we provide our clients with the added edge of setting their own shipping requirements for time, volume, sequence and packaging needs.

Whether we are delivering to our client’s store or their warehouse, we always take the quickest and most efficient route from our textile manufacturing plants or our storage facilities around the world. As global distributors we are familiar with all product compliance standards and take the hassle out of product requirement for quality management practices, environmental management and safety-related measures.

brands.

First Floor, 147 Chiswick High Road, London, W4 2DT, United Kingdom +44 (0) 203 962 8875